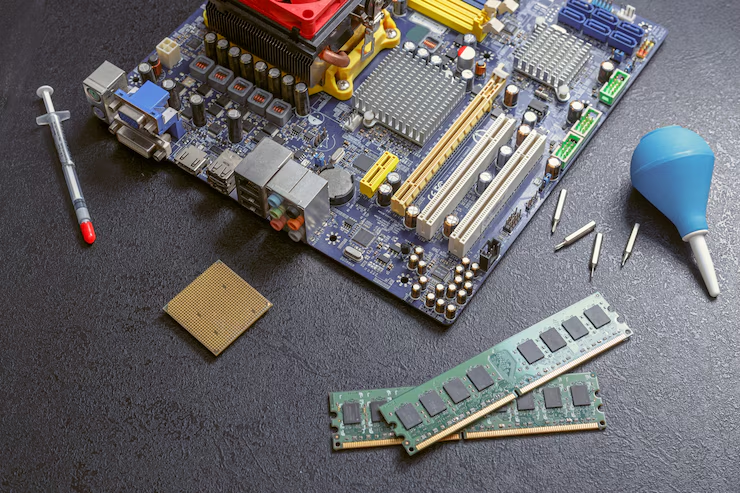

The journey from concept to reality in hardware product design is a complex and iterative process that begins with an idea and culminates in a market-ready product. Initially, designers engage in brainstorming sessions to generate a wide range of ideas, which are then refined through feasibility studies and market research. This stage involves understanding user needs, competitive analysis, and identifying key features that will differentiate the product in the market. Once a viable concept is identified, designers create detailed sketches and 3D models to visualize the product. These models serve as the foundation for creating prototypes, which are tested and evaluated to identify any design flaws or areas for improvement. Iterative testing and refinement are crucial, as they ensure that the final product meets all design specifications and user requirements. The transition from prototype to production involves rigorous quality control and testing to ensure that the product can be manufactured at scale while maintaining high standards of quality and reliability. This journey is a testament to the creativity, technical prowess, and perseverance of designers who transform innovative ideas into tangible products that enhance our daily lives.

Leveraging AI And Machine Learning In Hardware Product Design

The integration of AI and machine learning into hardware product design is revolutionizing the way designers approach problem-solving and innovation. AI algorithms can analyze vast amounts of data to identify patterns and trends, providing designers with valuable insights into user behavior, material performance, and manufacturing processes. Machine learning models can optimize design parameters by predicting the impact of various design choices on product performance and manufacturability. For instance, generative design algorithms can explore a multitude of design alternatives based on specified constraints, such as weight, strength, and cost, enabling designers to identify optimal solutions that might not be immediately apparent through traditional methods. Additionally, AI-driven simulation tools can model and predict the behavior of complex systems under different conditions, allowing for more accurate and efficient testing and validation. This not only accelerates the design process but also enhances the overall quality and functionality of the final product. The integration of AI and machine learning into hardware product design represents a significant leap forward, enabling more innovative, efficient, and user-centric products.

Prototyping Techniques In Modern Hardware Product Design

Prototyping is a critical phase in hardware product design, allowing designers to transform theoretical models into tangible forms that can be tested and refined. Modern prototyping techniques have advanced significantly, offering a range of options to suit different stages of the design process. Traditional methods, such as hand-crafted models and CNC machining, are now complemented by cutting-edge technologies like 3D printing and rapid prototyping. 3D printing, in particular, has revolutionized prototyping by enabling designers to quickly produce complex geometries and functional parts with a high degree of precision. This technology allows for rapid iteration, reducing the time and cost associated with traditional prototyping methods. Additionally, virtual prototyping tools, such as CAD software and virtual reality simulations, provide a digital platform for testing and refining designs before physical prototypes are created. These tools enable designers to identify and address potential issues early in the development process, enhancing the overall efficiency and effectiveness of the design. By leveraging modern prototyping techniques, designers can accelerate the development cycle, reduce costs, and improve the quality and functionality of the final product.

Ergonomics And Aesthetics In Hardware Product Design

Ergonomics and aesthetics play a crucial role in hardware product design, influencing both the usability and appeal of the final product. Ergonomics focuses on designing products that are comfortable and intuitive to use, reducing the risk of injury and enhancing user satisfaction. This involves considering factors such as the shape, size, and weight of the product, as well as the placement of controls and interfaces. Ergonomic design is particularly important in products that are used frequently or for extended periods, such as consumer electronics, tools, and medical devices. Aesthetics, on the other hand, pertains to the visual and tactile appeal of the product. A well-designed product not only performs its intended function effectively but also looks and feels good, creating a positive emotional response in users. Achieving a balance between ergonomics and aesthetics requires a deep understanding of both the physical and psychological aspects of user experience. Designers must consider how the product will be used, who will be using it, and the context in which it will be used, ensuring that the final design is both functional and attractive. The integration of ergonomics and aesthetics into hardware product design results in products that are not only effective and efficient but also enjoyable to use and visually appealing.

Cost-Effective Strategies For Hardware Product Design

Designing hardware products cost-effectively is essential for ensuring market viability and competitiveness. Cost-effective strategies begin with the initial design phase, where designers aim to optimize the use of materials and manufacturing processes. One approach is Design for Manufacturability (DFM), which involves designing products in a way that simplifies manufacturing and assembly, reducing production costs and time. This can include minimizing the number of parts, using standard components, and designing for ease of assembly. Another important strategy is Design for Sustainability (DFS), which focuses on reducing material waste and energy consumption throughout the product’s lifecycle. This can involve selecting eco-friendly materials, designing for recyclability, and implementing energy-efficient manufacturing processes. Additionally, leveraging modern prototyping and simulation tools can help identify cost-saving opportunities early in the design process, reducing the need for expensive modifications later on. By adopting these strategies, designers can create high-quality products that meet market demands while keeping costs under control. Cost-effective design not only benefits the manufacturer but also makes innovative and high-quality products accessible to a wider range of consumers.

Collaborative Hardware Product Design: Teamwork And Communication

Effective teamwork and communication are critical components of successful hardware product design. The complexity of modern hardware products requires the collaboration of multidisciplinary teams, including industrial designers, engineers, marketers, and supply chain specialists. Clear and open communication ensures that all team members are aligned on project goals, timelines, and deliverables, facilitating a cohesive and efficient design process. Collaborative tools, such as project management software, shared design platforms, and real-time communication channels, play a vital role in maintaining synchronization among team members. Regular meetings, design reviews, and feedback sessions help to identify and address issues early, ensuring that the project stays on track and meets its objectives. Additionally, fostering a culture of collaboration and mutual respect within the team encourages creativity and innovation, as team members feel empowered to share ideas and perspectives. Effective collaboration not only enhances the quality of the final product but also contributes to a more efficient and enjoyable design process. By leveraging the strengths and expertise of each team member, collaborative hardware product design leads to more innovative, user-centric, and successful products.

Challenges And Solutions In IOT Hardware Product Design

Designing hardware for the Internet of Things (IoT) presents unique challenges and requires innovative solutions to address them. One of the primary challenges is ensuring seamless connectivity and interoperability among a diverse range of devices and systems. This requires careful selection of communication protocols and standards, as well as robust testing to ensure compatibility. Another challenge is power management, as IoT devices often need to operate on limited power sources, such as batteries or energy harvesting systems. Designers must optimize power consumption through efficient hardware design and low-power communication techniques. Security is also a critical concern, as IoT devices are often vulnerable to cyber-attacks. Implementing strong encryption, secure boot processes, and regular firmware updates are essential to protect against security threats. Additionally, the miniaturization of IoT devices poses challenges in terms of component integration and thermal management. Advanced manufacturing techniques, such as System-in-Package (SiP) and 3D integration, can help address these challenges by enabling compact and efficient designs. By adopting innovative solutions and staying abreast of technological advancements, designers can overcome the challenges of IoT hardware product design and create reliable, secure, and efficient devices.

The Impact Of Rapid Prototyping On Hardware Product Design Efficiency

Rapid prototyping has had a transformative impact on the efficiency of hardware product design, enabling faster iteration and development cycles. By allowing designers to quickly create physical models of their designs, rapid prototyping facilitates immediate testing and feedback, significantly reducing the time and cost associated with traditional prototyping methods. Techniques such as 3D printing, CNC machining, and laser cutting enable the rapid production of prototypes with high precision and detail. This accelerates the identification and resolution of design issues, allowing for more iterations in a shorter timeframe. Additionally, rapid prototyping supports parallel development processes, where multiple design variations can be tested simultaneously, further enhancing the efficiency of the design process. The ability to quickly produce and test prototypes also fosters greater innovation, as designers can experiment with unconventional ideas and concepts without the risk of significant time or financial investment. Overall, rapid prototyping has revolutionized hardware product design by enabling more agile and iterative development processes, resulting in faster time-to-market and more innovative, high-quality products.

Conclusion

Hardware product design is a dynamic and multifaceted discipline that requires a blend of creativity, technical expertise, and practical knowledge. From the initial concept to the final product, designers must navigate a complex and iterative process, leveraging modern technologies and methodologies to create innovative and user-centric products. The potential for transformative products that enhance lives, improve industries, and contribute to a sustainable future makes the journey worthwhile. By staying attuned to emerging trends and consumer needs, hardware startups can carve out successful niches and drive the next wave of technological advancement.

Leif Aleksandra, a nomadic wordsmith with roots spanning continents, captures the essence of diverse cultures in his tales. With a pen dipped in wanderlust, Leif traverses the landscapes of imagination, blending the flavors of his global experiences into narratives that resonate with universal truths.